Deammonification = EssDe ®

S::Select ®

|

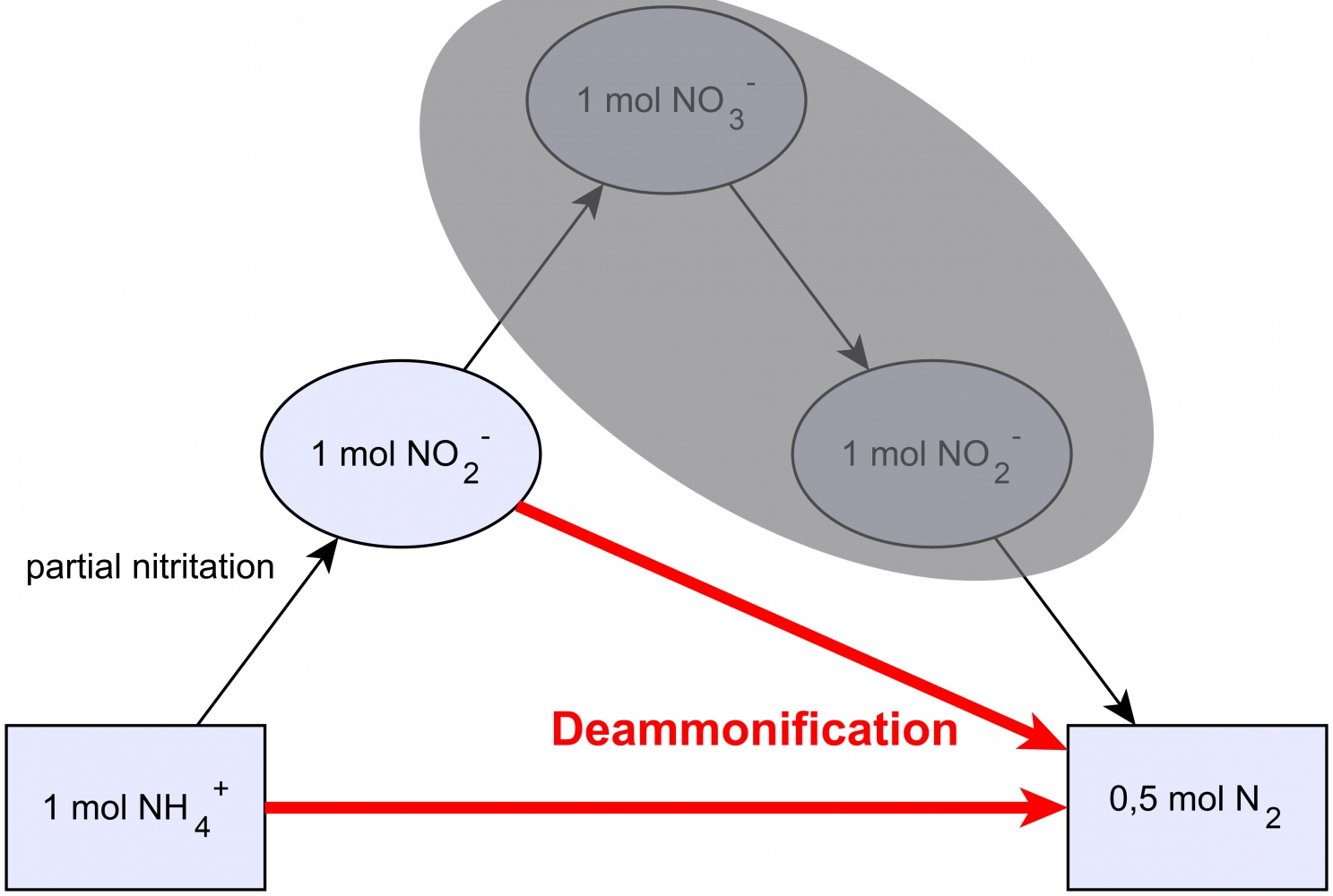

Aside from sludge treatment, deammonification resp. nitrogen removal is an important cost factor in wastewater treatment. The EssDe® process is a very efficient and cost effective solution for nitrogen removal. During anaerobic fermentation in the digester of a biogas or sewage plant, the nitrogen bound in the organics is released as ammonium nitrogen (NH4-N). The centrate of dewatered digested sludge is heavily contaminated with NH4-N. Treatment in the wastewater treatment plant without deammonification is cost-intensive and puts additional load onto the biological reactor basins. Conventional nitrification/denitrification converts ammonium to nitrite and then to nitrate using specialized bacteria. However, nitrate must then be denitrified again by adding an external carbon source. |

|

| In 1997, we installed the first deammonification plants with separate treatment of process water (for example Bern / CH and Glarnerland / CH), in which denitrification was based on nitrite (denitritation). By avoiding the intermediary step to and from nitrate, 25% energy and 40% carbon (methanol) could be saved. |

|

| With the deammonification using the EssDe® process, only 50% of the ammonium is oxidized to nitrite. Subsequently, the produced nitrite is reduced to nitrogen gas along with the remaining ammonium. Compared to conventional nitrification / denitrification, this results in savings of around 60% in energy consumption. The consumption of external carbon, which is the main cost factor of the process water treatment, is reduced to zero. | |

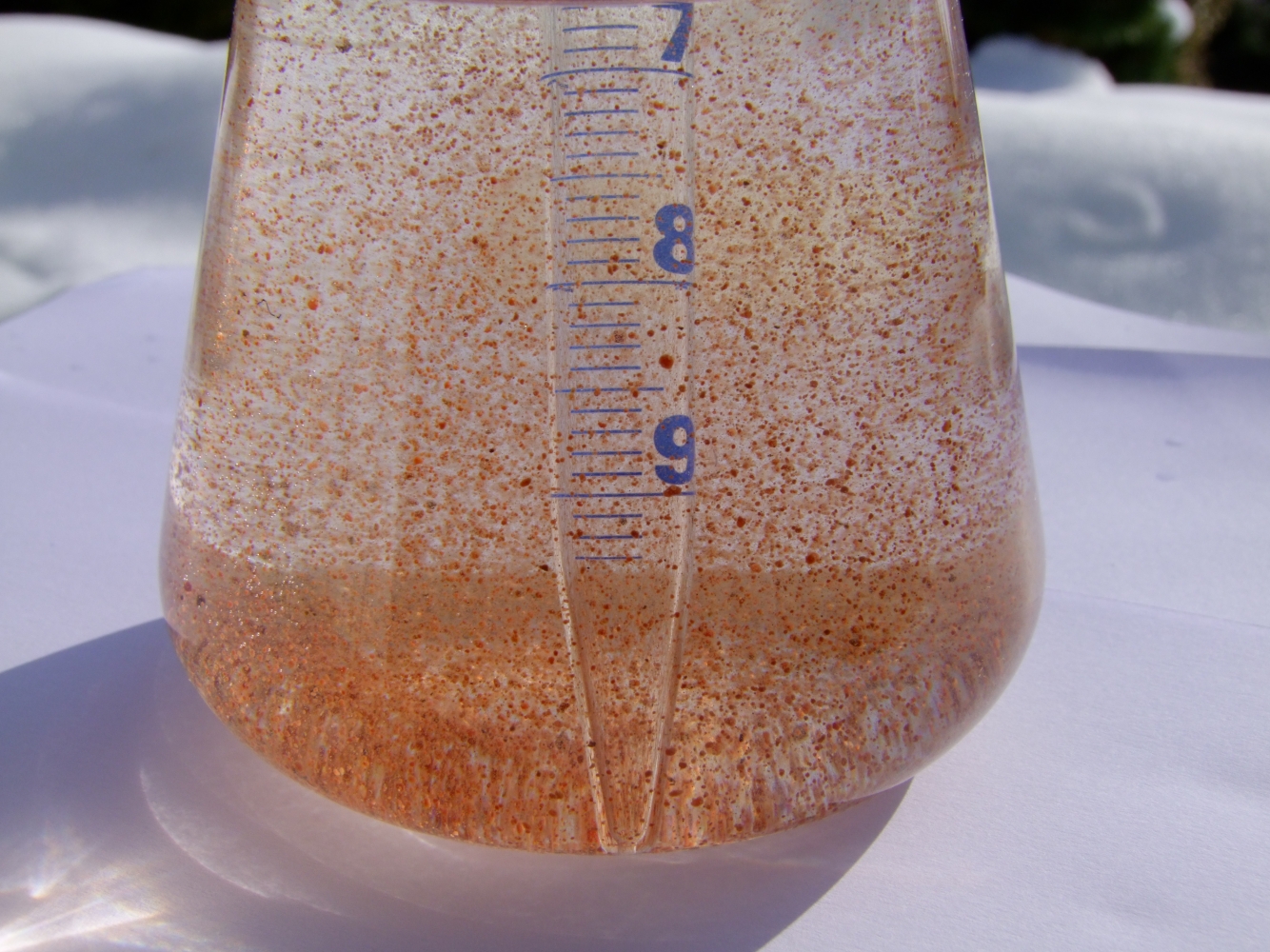

| This process for eliminating ammonium from process water is carried out in an SBR or a continuously operated plant. The intensive red color of the biological sludge is typical for the EssDe® process, the deammonification. The anaerobic bacteria form large granules in dense packing (1010 cells ml-1) which have good settling properties. The growth rate of this sludge is very low, which is why a high sludge age (SRT) is mandatory. |

|