Deammonification = EssDe ®

S::Select ®

|

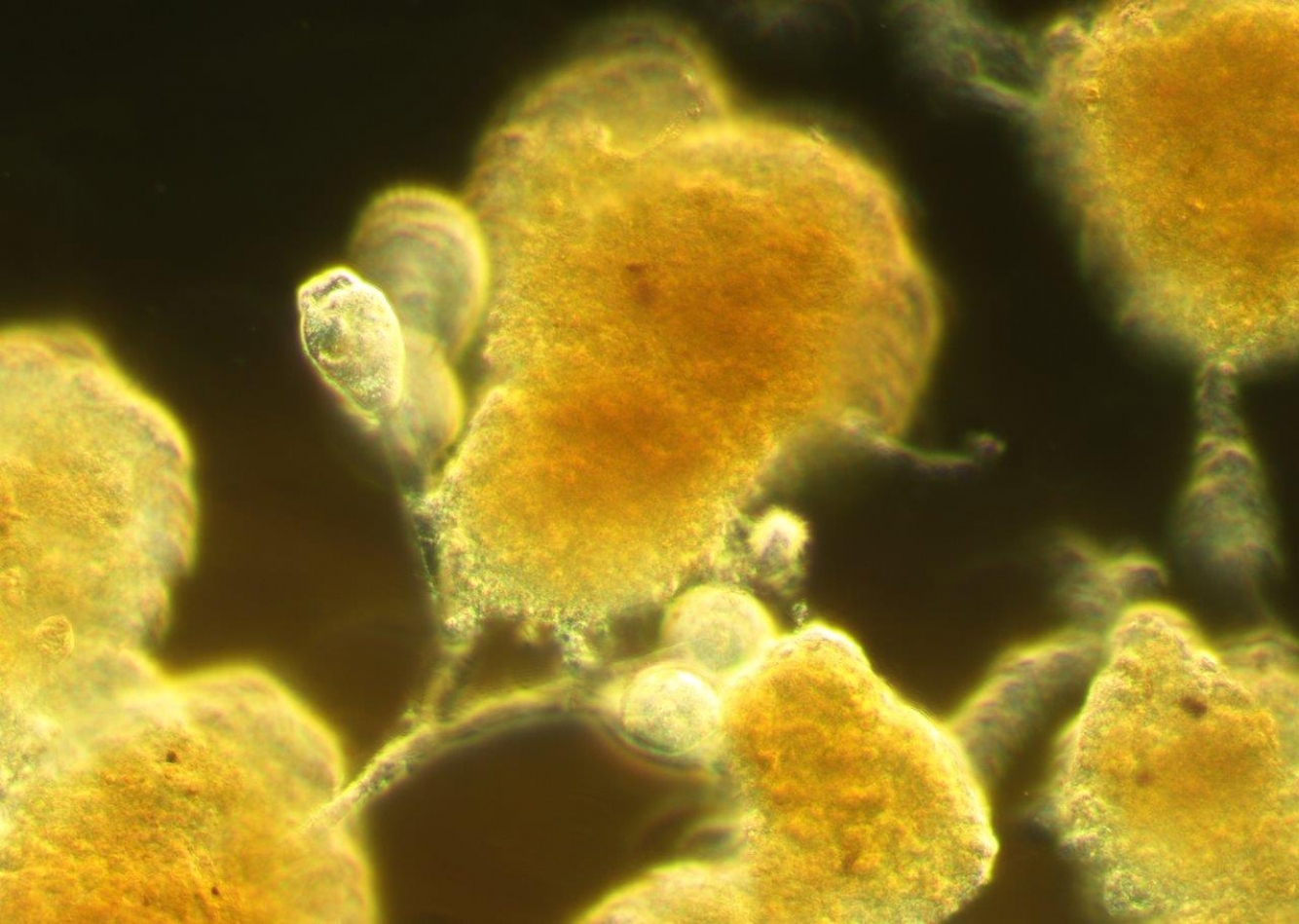

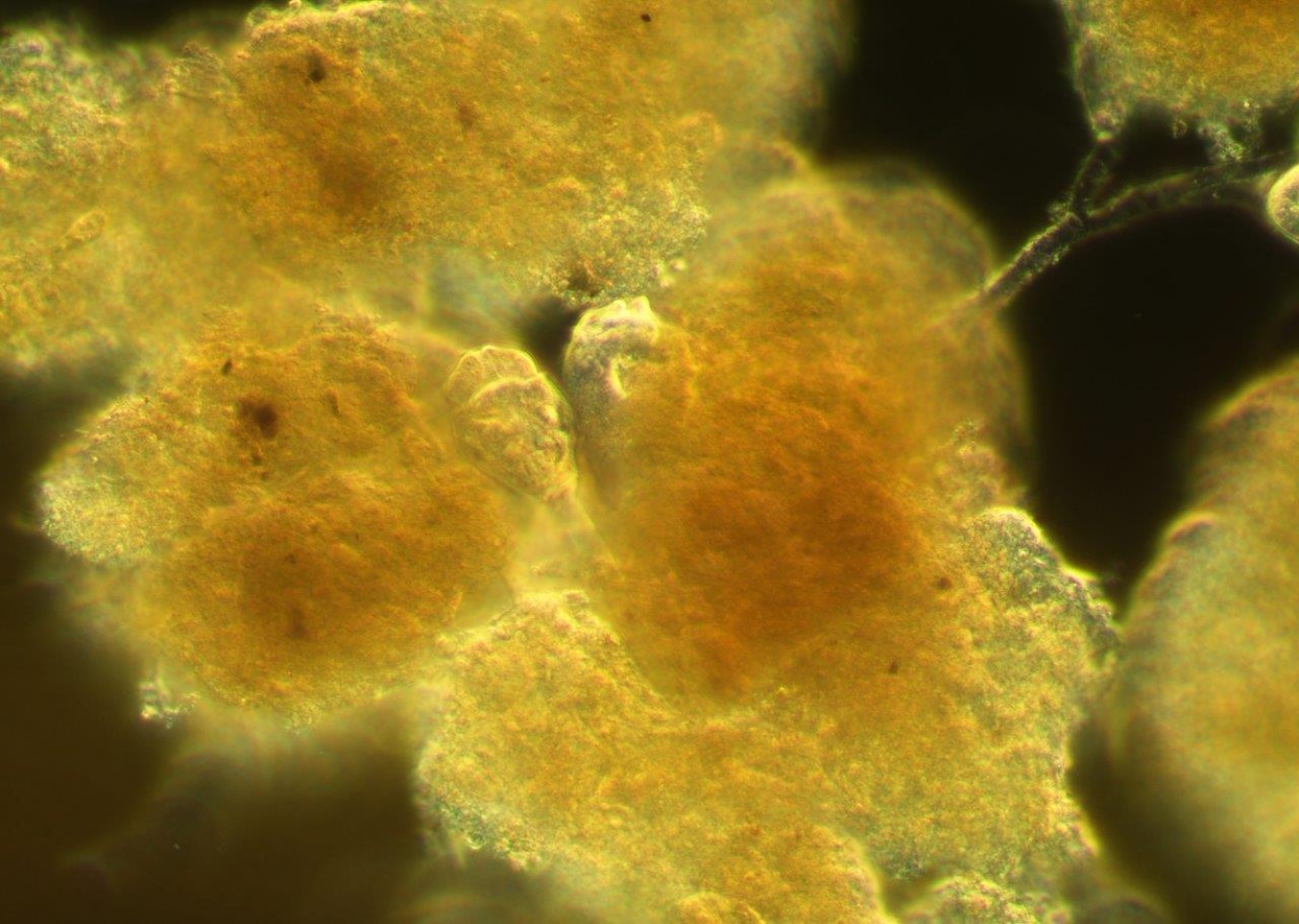

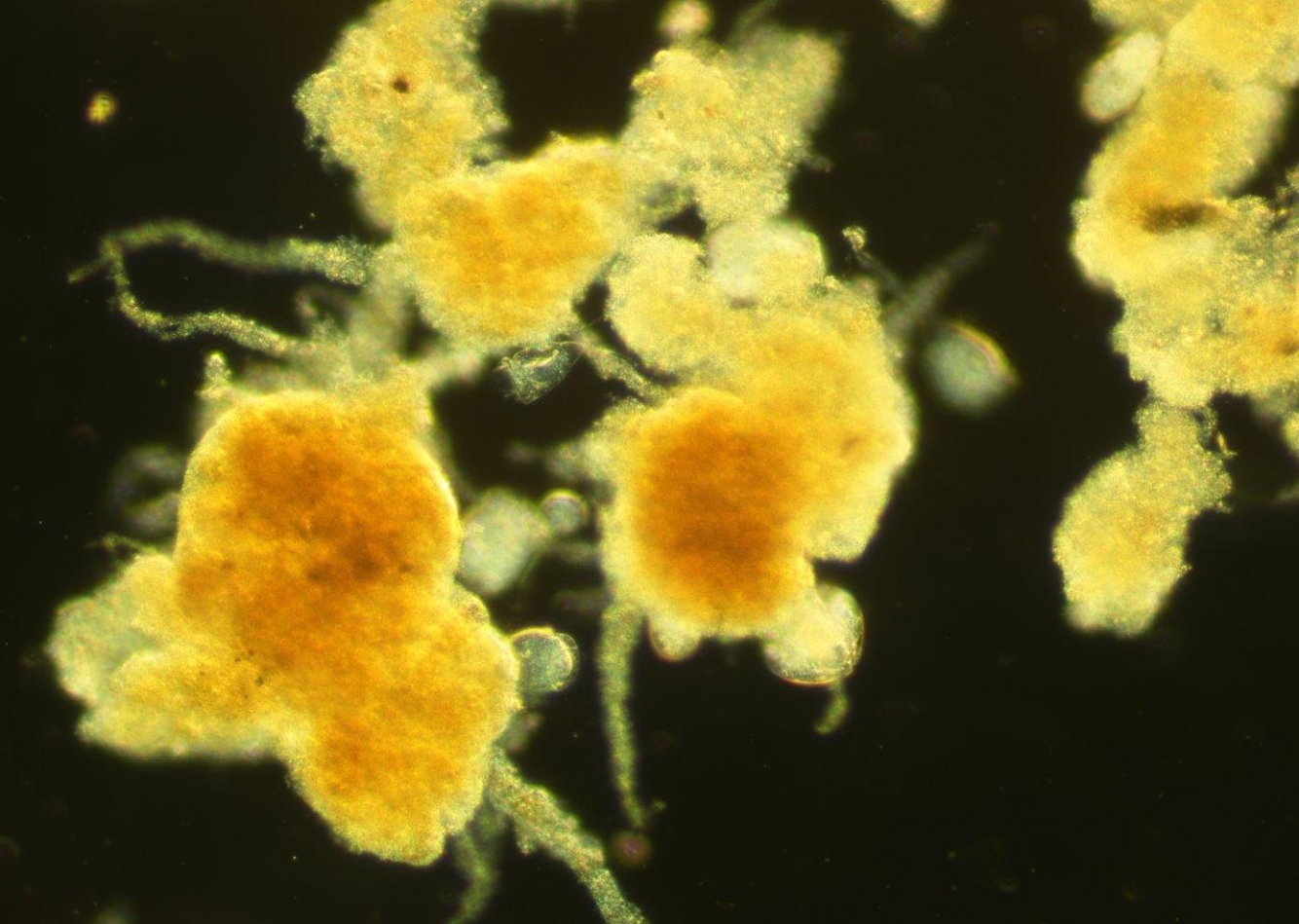

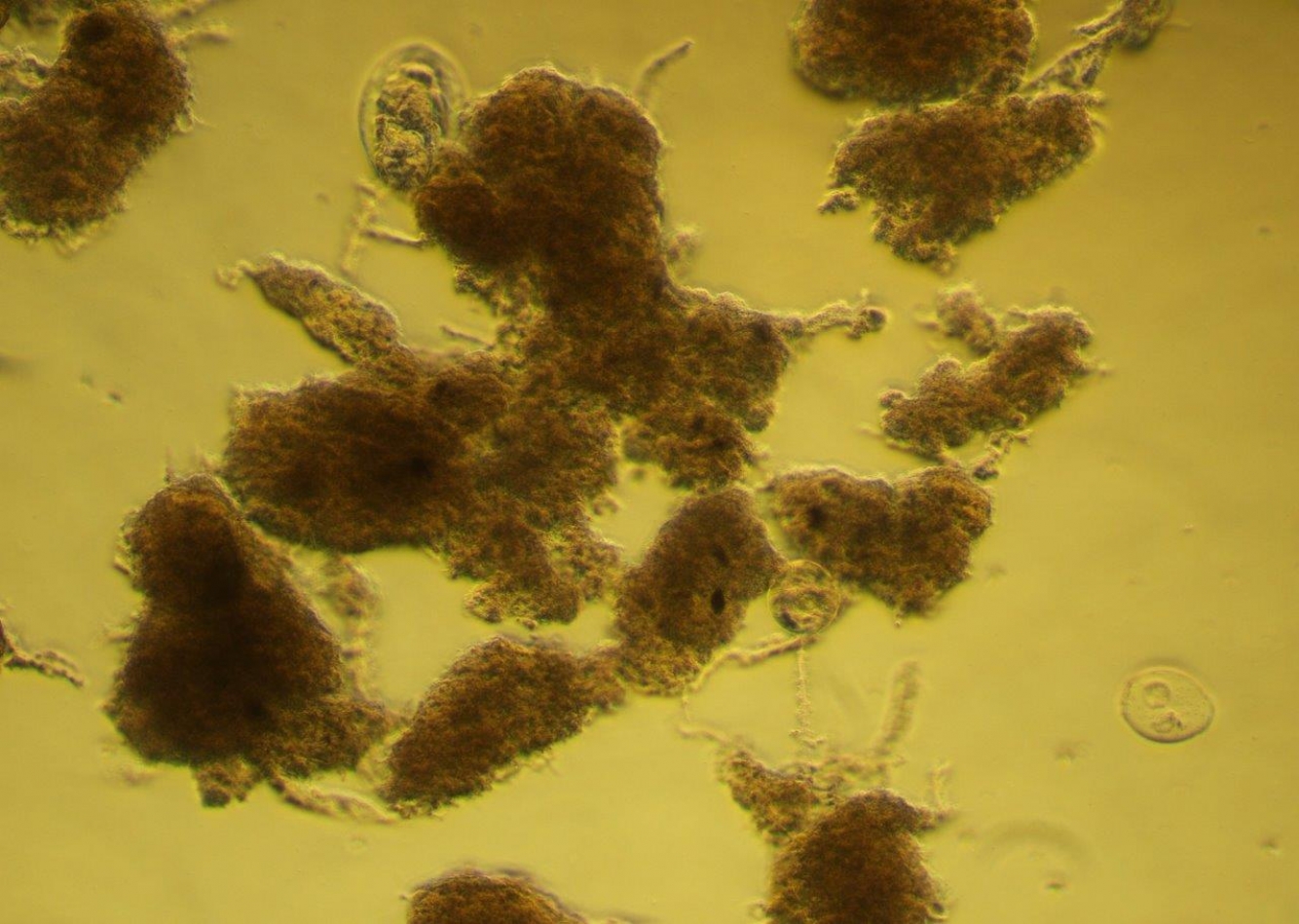

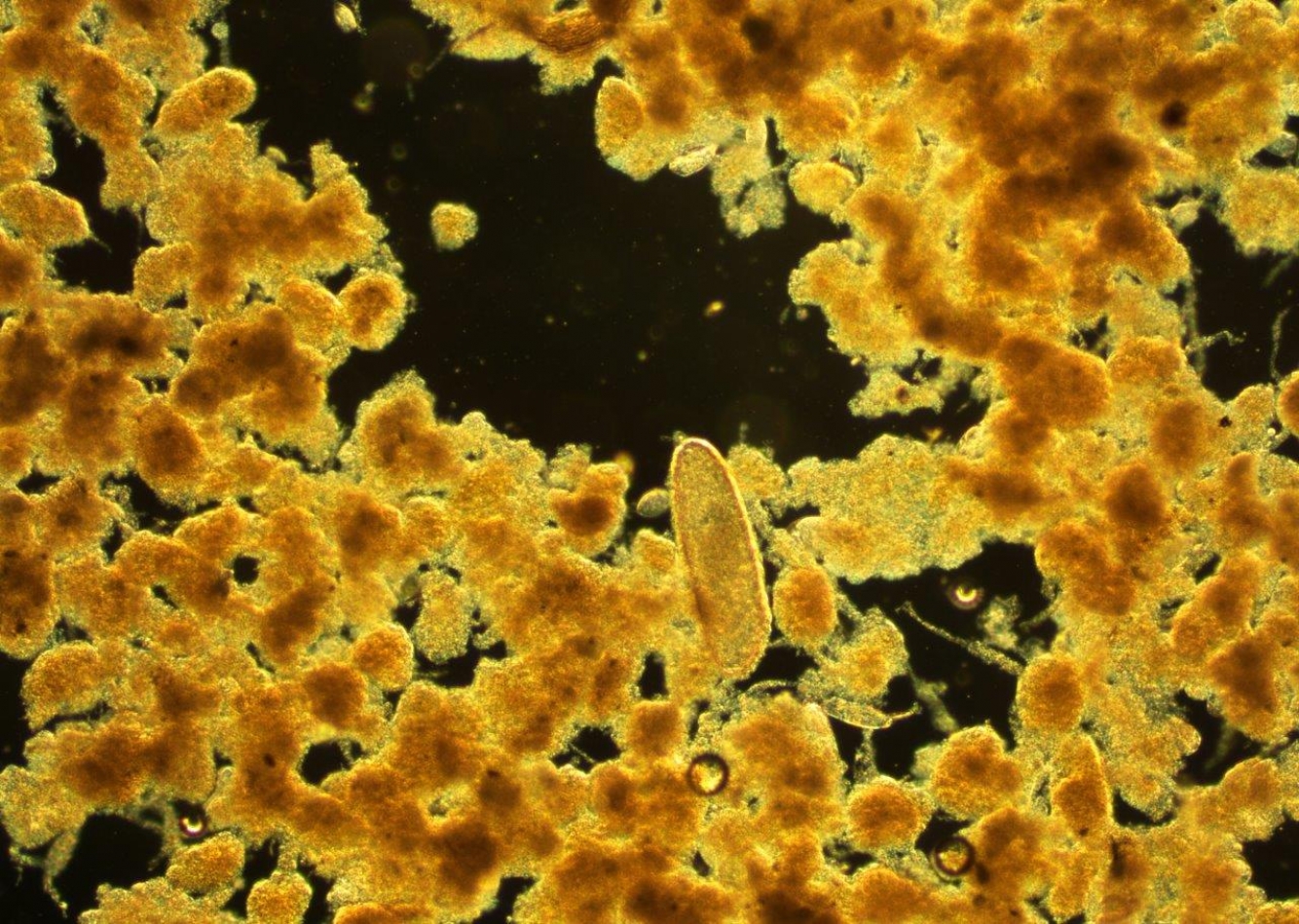

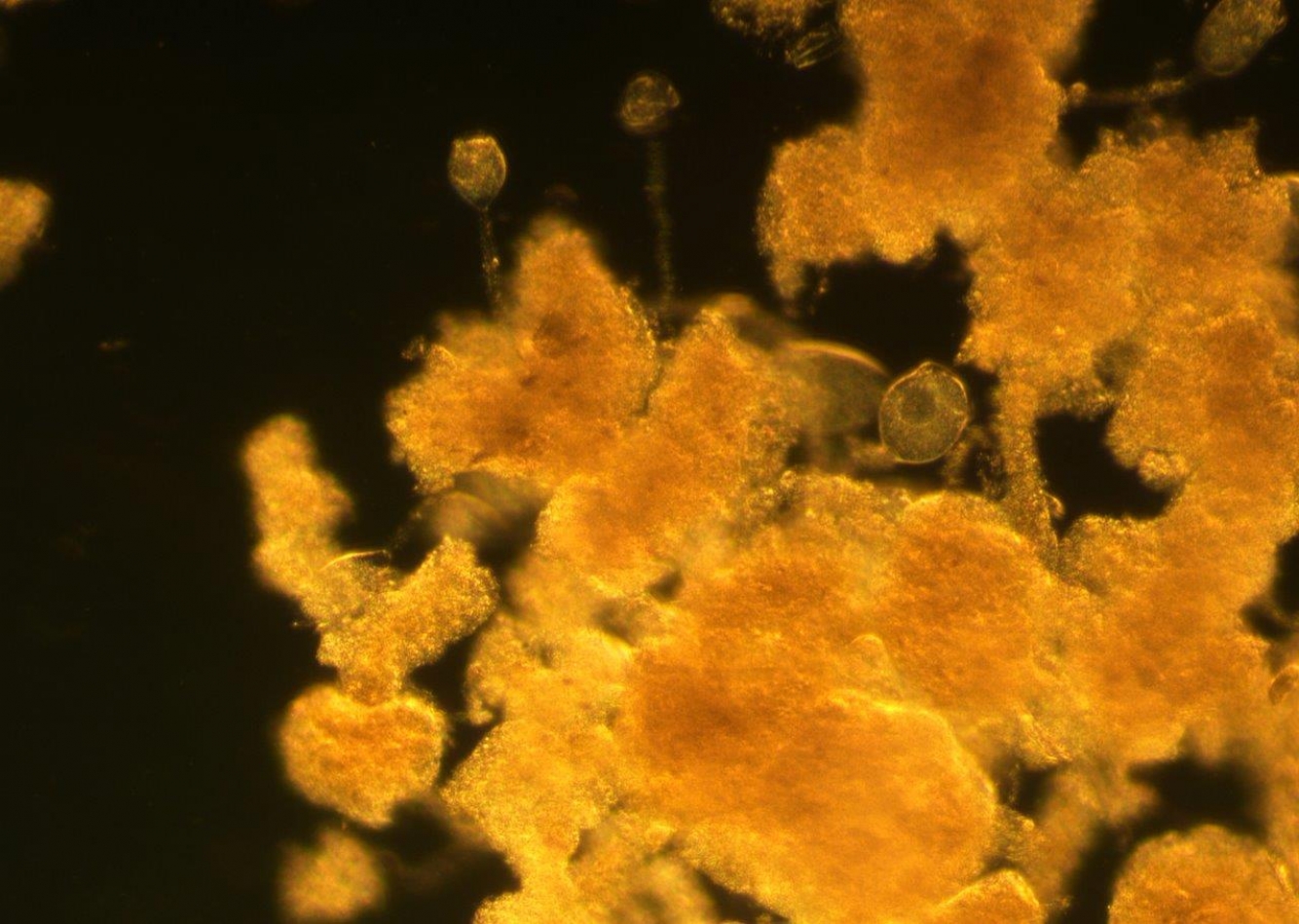

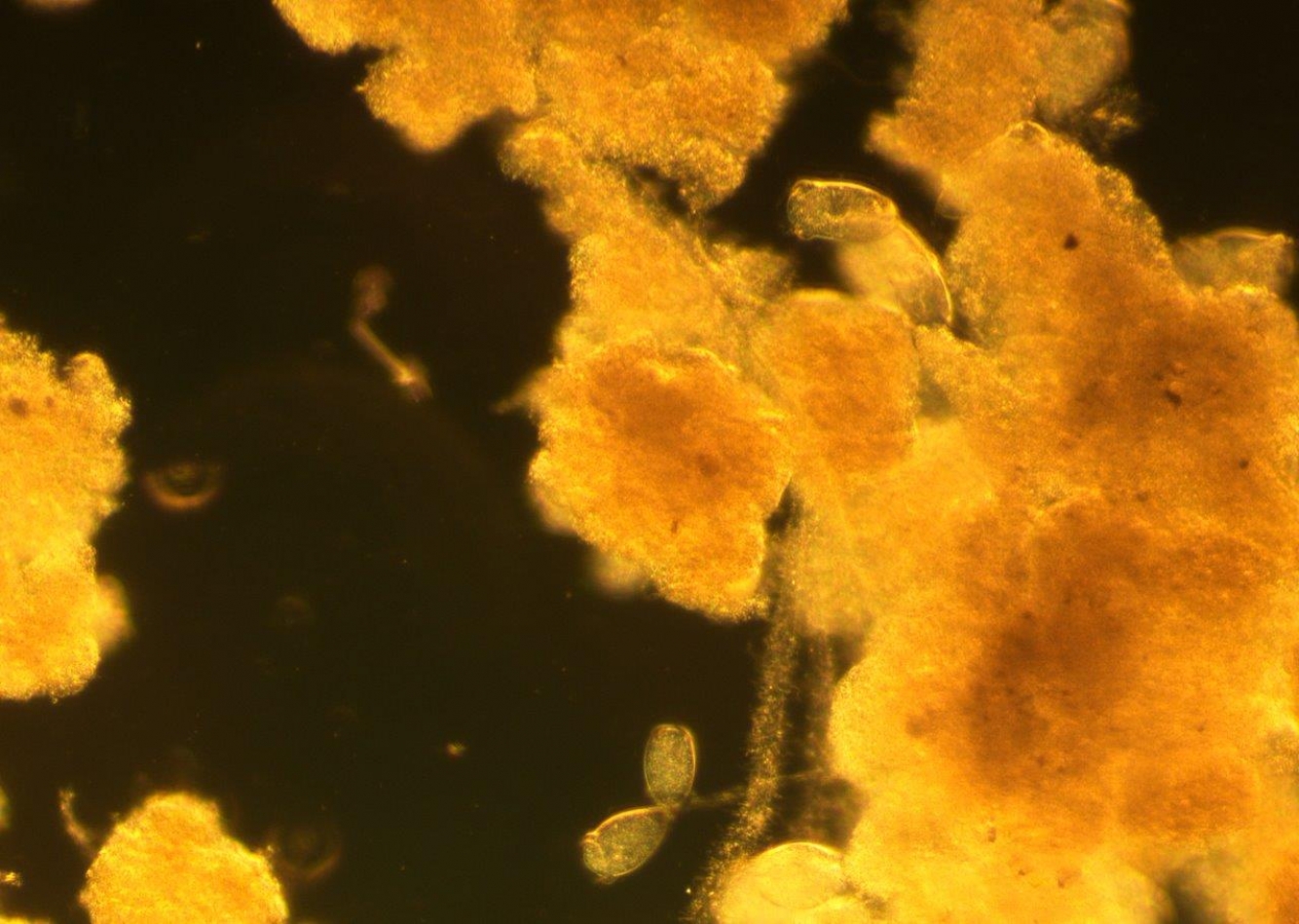

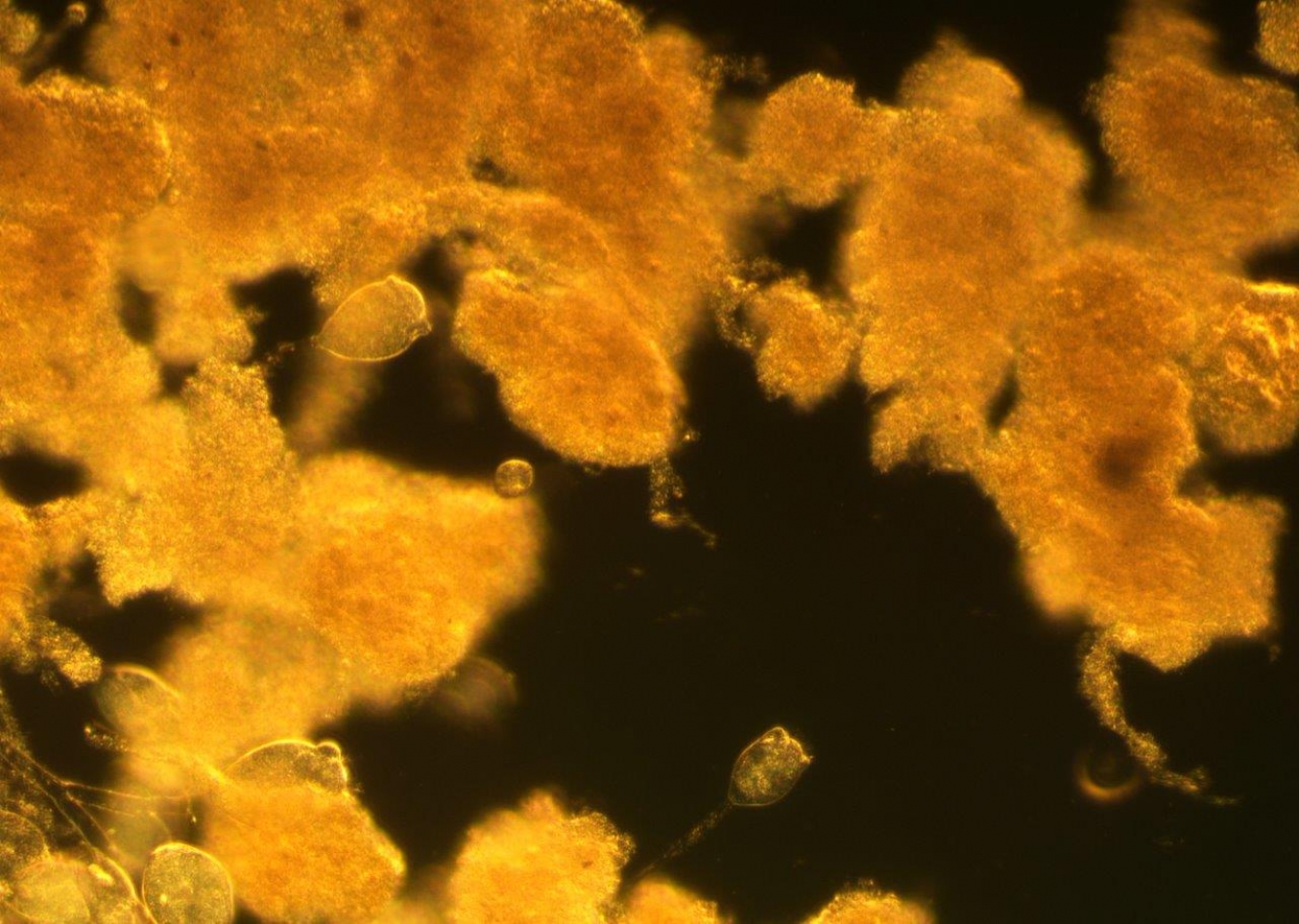

The greatest portion of a wastewater treatment plant’s aeration energy is expended on nitrogen oxidation (nitrification). During the subsequent denitrification, carbon is again added. However, it would be more advantageously to convert this carbon into methane inside the digesters. It therefore seems obvious to also employ the EssDe® process in the mainstream. EssDe® is already considered a state of the art sidestream application. It is autotrophic, does not demand carbon, and requires only 40% of the oxygen as compared to conventional nitrification. This is countered by the fact that the deammonifying bacteria (Planctomycetes) are extremely slow-growing. At the same time, the rate of growth is directly linked to the water temperature, which in the mainstream is very much lower than in the sidestream. Thus, the combination of sidestream and mainstream is crucial in order to produce the slow-growing bacteria under favorable conditions in the sidestream and then transport the surplus into the mainstream. |

|

| However, provided that these bacteria cannot be selectively kept in the system, the planctomycetes will be lost quickly via the waste sludge (WAS) of the mainstream. Selective retention is achieved by separating the planctomycetes from the waste sludge and then recycling them to the biological reactor basins. This process is also patent of EssDe GmbH. |

|

| In addition, deammonification always demands nitrite. In the mainstream, however, competition by the NOBs, i.e. nitrite-oxidizing bacteria, is very strong. The AOB's must be strengthened by means of additional measures in such a way that a nitrite surplus is ensured, which can then be consumed by the plantomycetes. | |

|

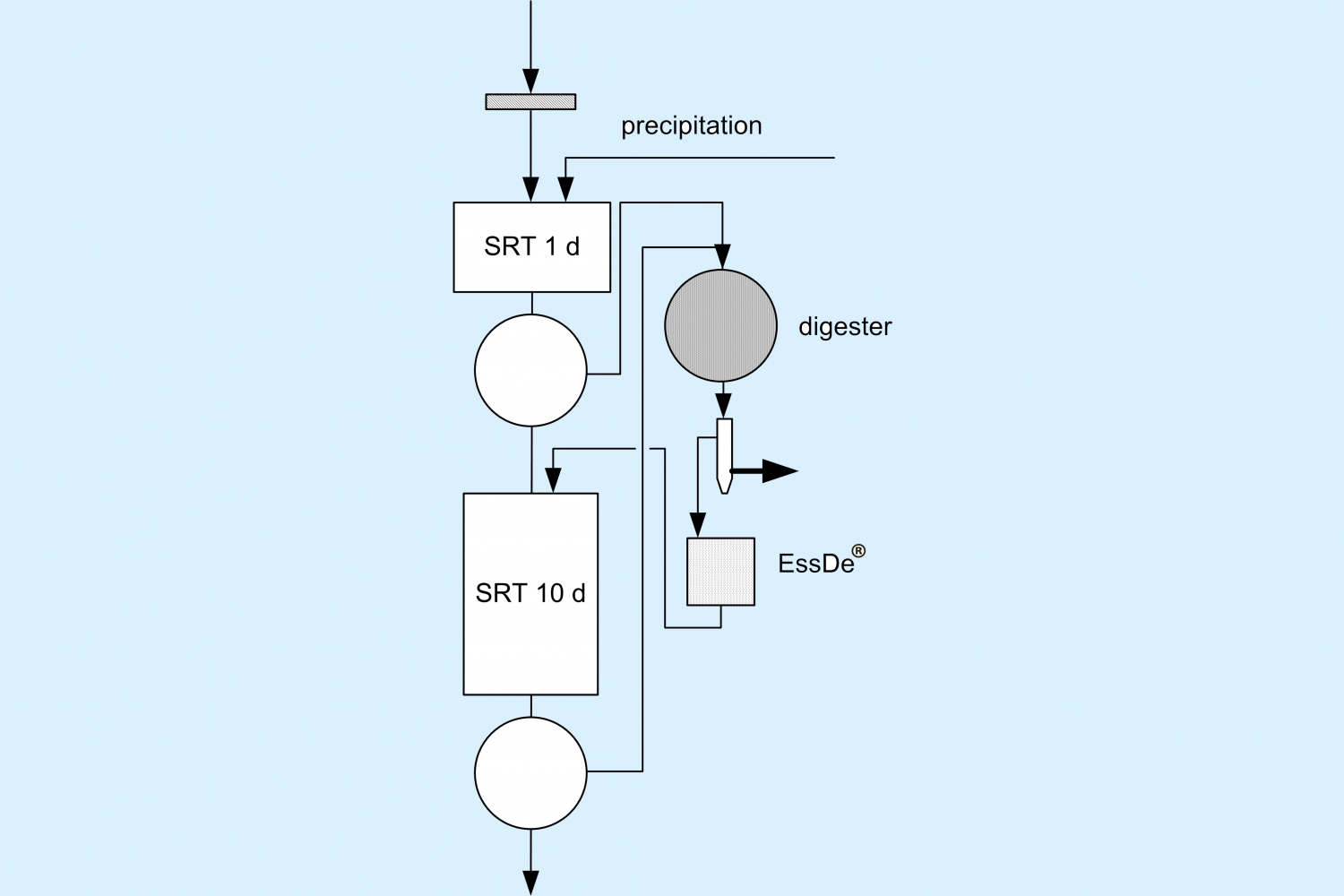

Additional energy optimization of an aeration system can then be achieved by a prior A-stage (adsorption stage). Most of the carbon is fixed in a very high loaded A-stage, possibly combined with a precipitation, then adsorbed and immediately pumped into the digestion. Not only does this save additional (aeration) energy by avoiding growth of activated sludge and endogenous respiration, it also produces a lot more gas and thus energy. The described concept has been known for many years as AB-stage process and has been implemented multiple times in large scale. The distinct disadvantage of this process was that a lack of sufficient carbon compromised denitrification in the poorly loaded B-stage. With the EssDe® process, the tool is now available to save and / or recover the maximum amount of energy, and at the same time achieve an almost complete nitrogen elimination. |

|

| Pollutants in the wastewater will no longer be seen as a problem but as an energy source. | |

| The benefits: • Maximum energy surplus, thanks to minimal oxygen consumption and maximized biogas production • Efficient nitrogen removal due to EssDe® in the sidestream and mainstream • Less total surplus sludge • Significantly improved sludge dewatering • Process conversion possible while keeping the existing plant structure | |

| A conversion of existing plants to the EssDe® concept is possible with comparatively little effort. Usually, the primary clarifications are oversized and separated into two trains. If one of these trains is used as a highly loaded biological stage, a large part of the concept has already been implemented. |