Deammonification = EssDe ®

S::Select ®

|

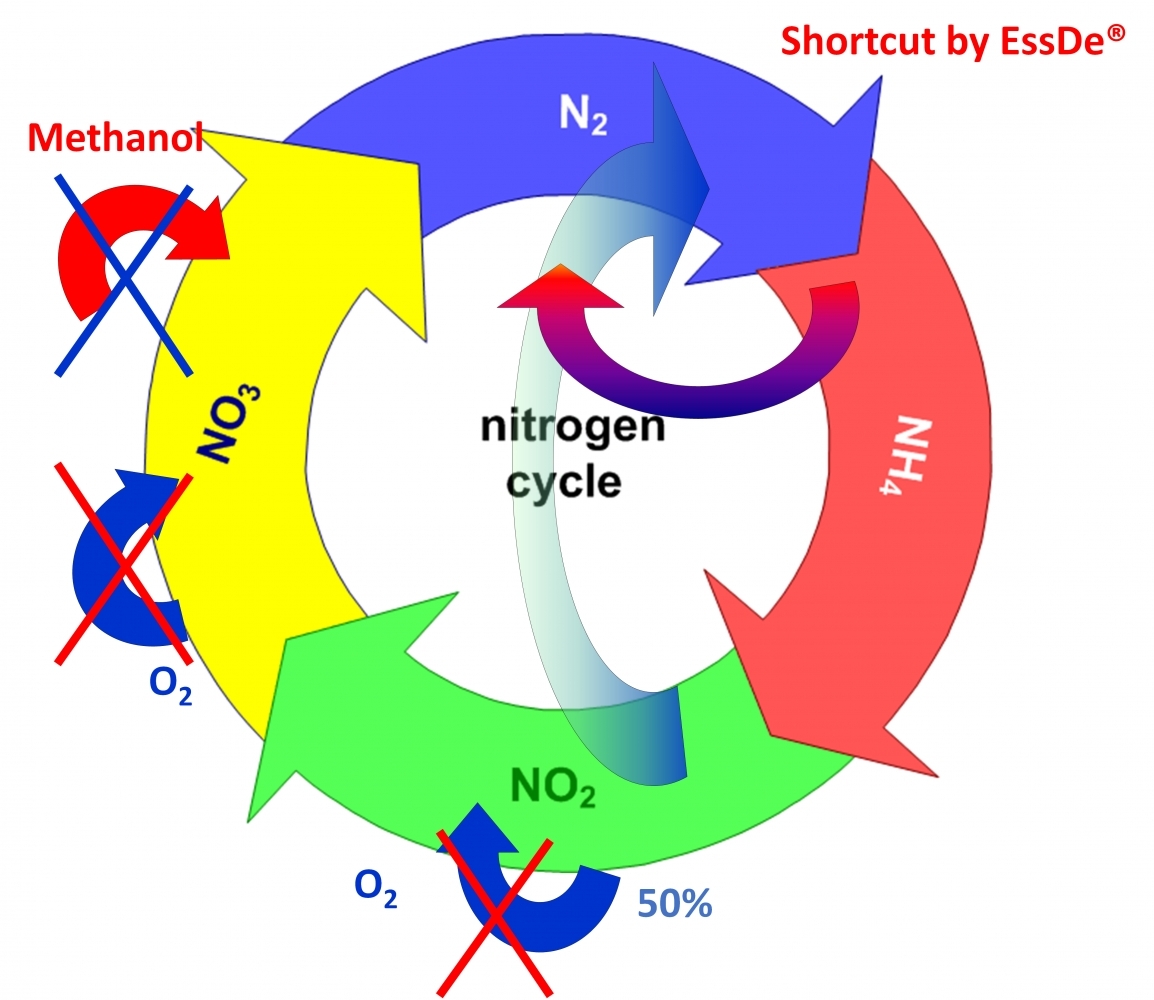

The EssDe® process stands for efficient nitrogen elimination by means of deammonification. This is followed by a maximum abbreviation for conventional nitrification and denitrification. Ammonium is only half oxidized to nitrite. The remaining ammonium and the nitrite formed are then reduced to elemental nitrogen with the help of specialized bacteria, the Planctomycetes. |

|

|

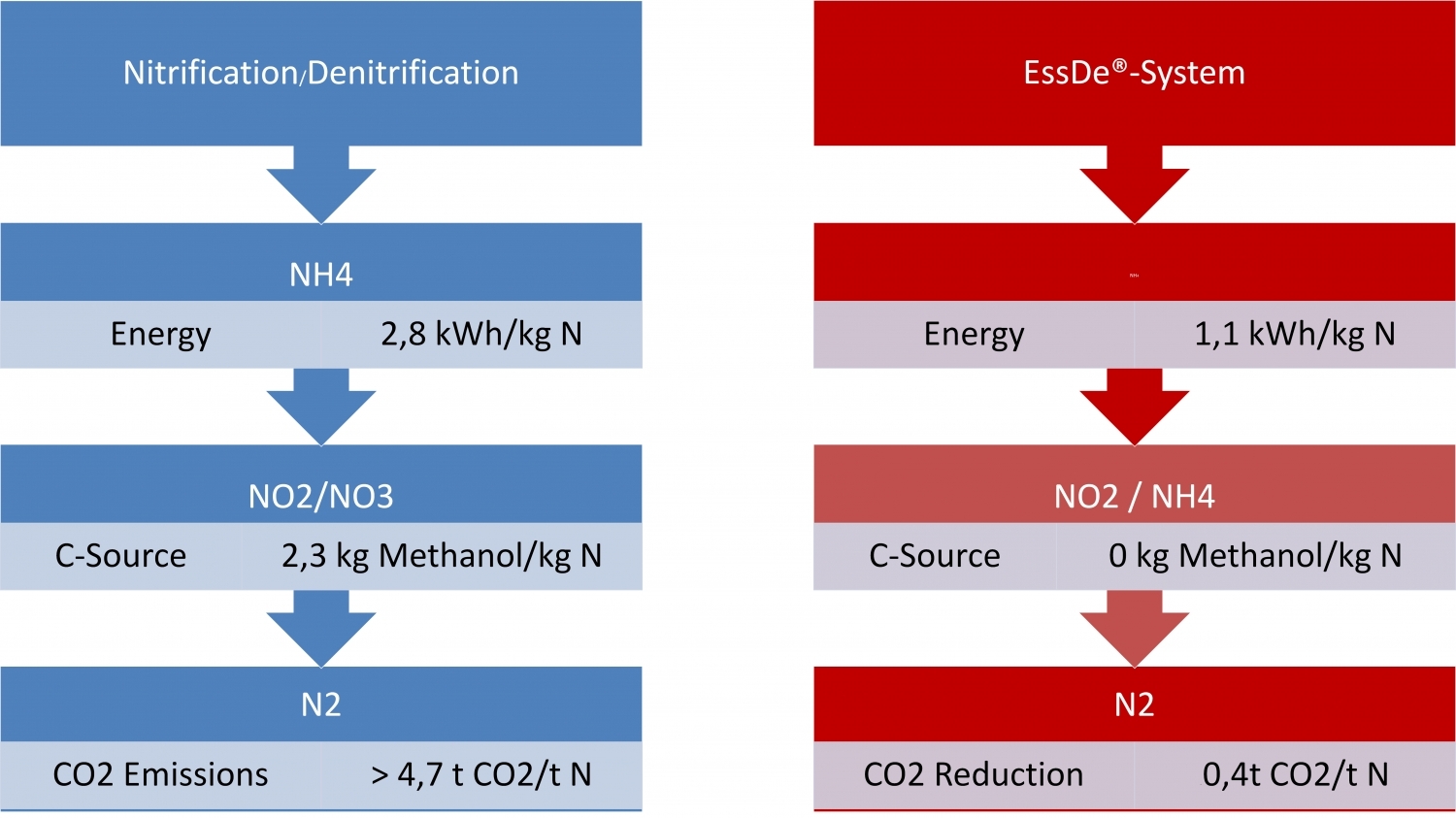

The partial nitritation, lack of nitrification and denitrification bring enormous economic advantages. An energy saving of around 60% is achieved. The operating costs for adding carbon are reduced to zero. The disposal costs for the surplus sludge are also greatly minimized. Since the EssDe® process runs autotrophically, there is an important ecological advantage. The EssDe® process consumes carbon dioxide (0.4 t CO2 / t N), while other biological processes produce large amounts of carbon dioxide (> 4.7 t CO2 / t N). |

|

|

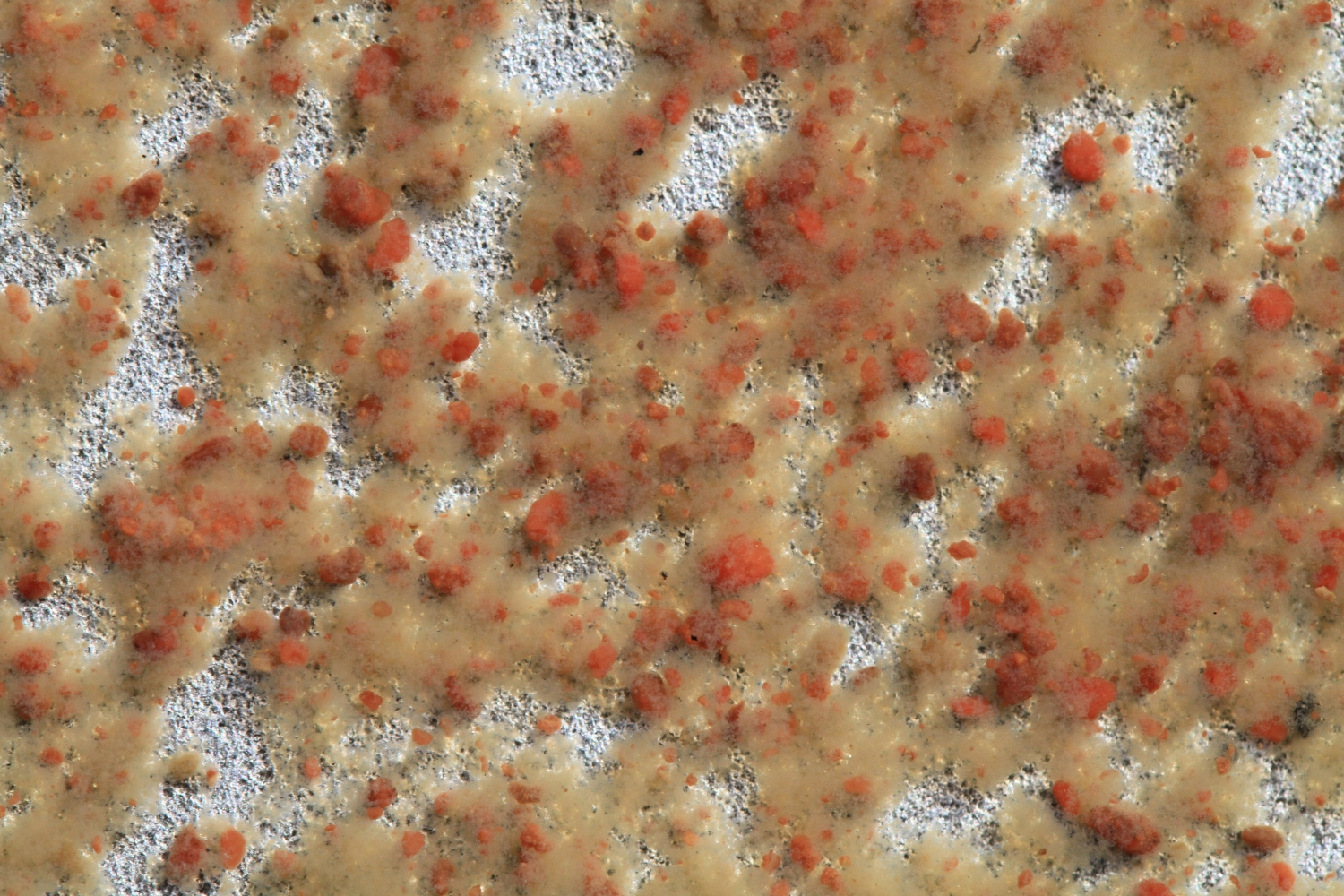

The EssDe® process is technically simple and robust. The operation of a plant is carried out continuously. This enables ideal living conditions for the bacteria involved in the process. The high operational stability of the EssDe® process is achieved through a balance between the nitrite-producing (aerobic) and -consuming (anaerobic) biology. The growth rate of the anaerobic fraction is very slow compared to that of the aerobic bacteria. Therefore, a high sludge age of the Planctomycetes and a low sludge age of the aerobes is required. There are 2 different sludge ages in an EssDe® reactor. |

|

|

Furthermore, it is imperative to keep the aerobic and fast-growing nitrate producers competing for nitrite out of the system. This problem is solved in the EssDe® process by selective separation of the excess sludge using the patented hydrocyclone technology. The repatriation of the Planctomycetes ensures an accumulation of these bacteria, which is why a system is more resilient and more resistant to disturbances. At the same time, the shear forces created in the hydrocyclones lead to the removal of disruptive diffusion barriers from the surface of the anaerobic organisms. The limitation of diffusion can be triggered by excess polymer or other constituents of the wastewater to be treated. The EssDe® process is typically used to treat municipal, highly concentrated process water (in the sidestream). For a quick start, a large amount of the granular, anaerobic inoculation sludge is made available in new systems. With the help of a control system and simple measurement technology, the EssDe® process guarantees stable process quality and easy control of the process flow. |

|